A strip brush is also a strip-shaped brush, it is a large type of brush, it can also be called strip brush or brush strip, its application range is very wide, such as furniture industry, cleaning industry, etc., and it is also a commonly used appliance in industry, The brush shaft can be made of 45# round steel, ordinary stainless steel, and 304# stainless steel, etc. According to different uses, the brush wire can be sisal, wool, PP wire, steel wire, stainless steel wire, copper-plated wire, copper wire, abrasive wire, and other materials.

It is generally used to block dust from movable doors and windows, revolving doors, sliding doors, automatic doors, and elevators to prevent dust from entering the interior; an extension product of the strip brush, the brush strip is spirally wound on the processed steel shaft, and both ends are welded and fixed. The characteristic is that the bristles are dense and do not fall off. It can also be made into hollow spring brushes according to the size, which can be installed and replaced by the customer, and the use cost is lower. The combination of spring brushes and rollers can produce solar panel cleaning brush rollers, which is also a common use of strip brushes.

Strip brushes are popular in Australia because strip brushes are often applied to door seals. Australia has a developed economy and abundant places. Every family has a car, and there must be a garage to store the car. Garages need to install sealing parts to protect the car from dust, insects, and depreciation.

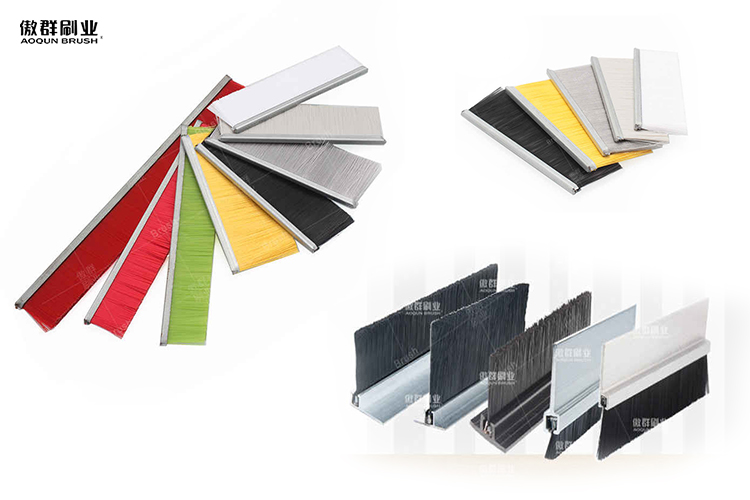

For the customization requirements of the strip brush, its base material, thickness, and side height have certain requirements, which can be manufactured according to the manufacturer’s requirements. The filaments can also be produced in various shapes on request, including round strip brushes. The widely used spring brush is actually a derivative of the strip brush, which is an additional winding process after the strip brush is generated.